Description

Our timber specification (Finished Sizes)

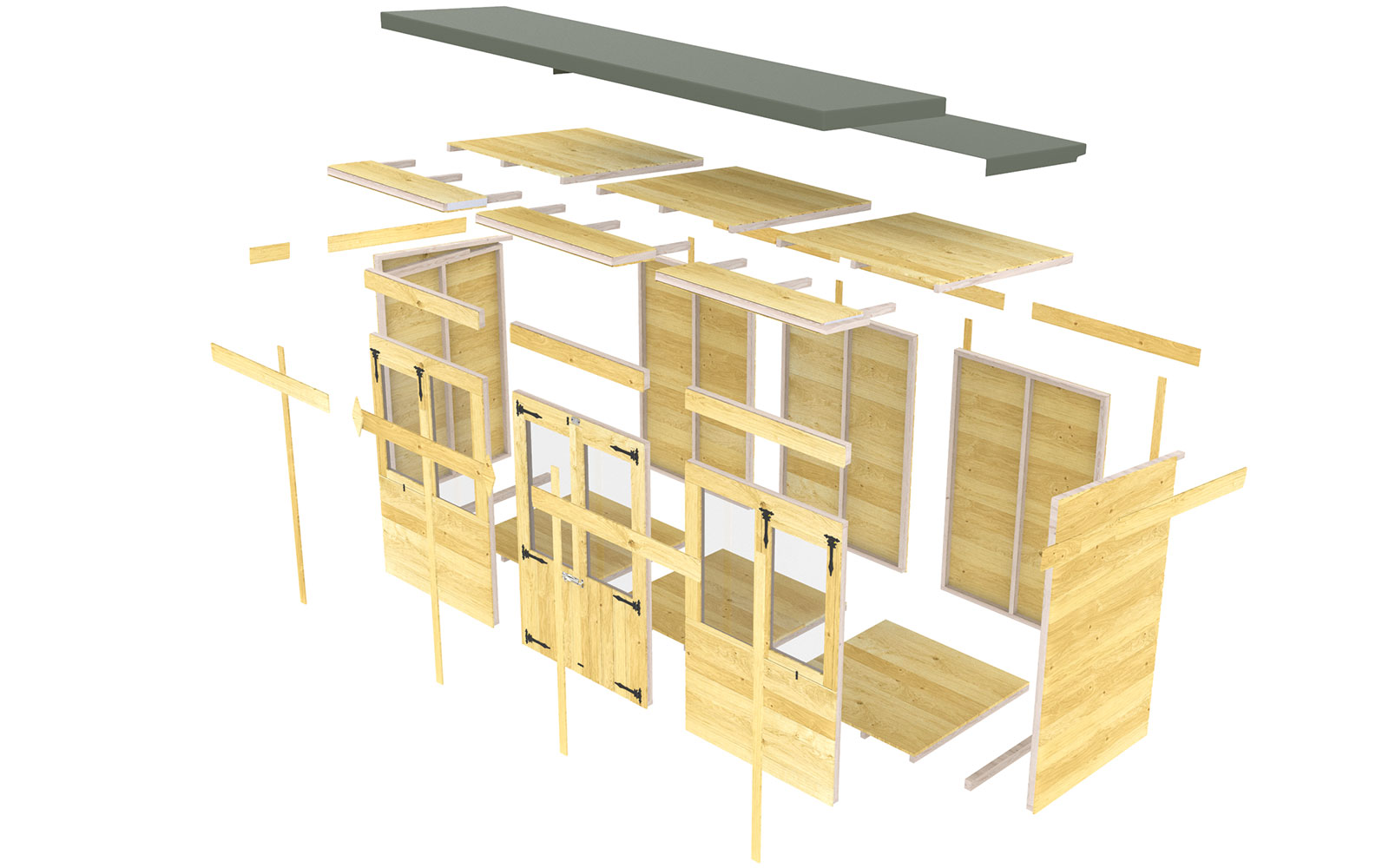

? 12mm Swedish Pressure Treated Tanalised Red-Wood Tongue & Groove Shiplap

38mm x 50mm Framework throughout the building (including roof and floor)

18mm Floor board pressure treated tanalised planks consisting of floor bearers attached underneath to elevate off the ground

12mm Swedish red-wood tongue & groove shiplap for the roof

4mm Horticultural glass

40kg Heavy duty modified bitumen mineral felt which is individually nail tacked on and not stapled

All our buildings are manufactured with pressure treated tanalised timber on the outside of the building to help against rotting, fungal and insect attack

All our buildings are fully framed throughout and screwed together during the manufacturing process and not stapled thus making it a much more stable building during the erecting process

Only galvanized nails are used throughout our building, as well as every cladded timber being double nailed for extra strength

All our buildings arrive with galvanised hinges, galvanised Brenton padbolts as standard.